27

Power Supply Facilities.

Power to the PUG Plant will be provided by PRECorp at 69 kilovolt-

ampere (kVA). A 20 megavolt-ampere (MVA) 69 kilovolt (kV)/4.16kV transformer and ancillary

equipment will be installed to reduce the voltage to the distribution network voltage of 4.16kV. A

capacitor bank will be installed to correct the power factor. The current design does not include

any redundancy to feed the plant in case of failure of the main transformer; however, an

emergency generator will be installed to provide power to critical equipment and utilities. The

current design provides for 60 percent of additional available capacity. The fire water system will

be diesel-powered and a minimum 100,000 gallons will be maintained in the tank at all times. A

motor control center will be built in the main PUG building. Large motors and heating elements

will be fed directly from the distribution line while small motors will be fed through two 2 MVA

4.16kV/480 volts (V) secondary step-down transformers at 480V.

Power Use.

The expected power consumption for the PUG Plant at peak production is 3,496

kilowatts (kW). Table 4.7-1 shows the electrical consumption of the PUG Plant during peak

production.

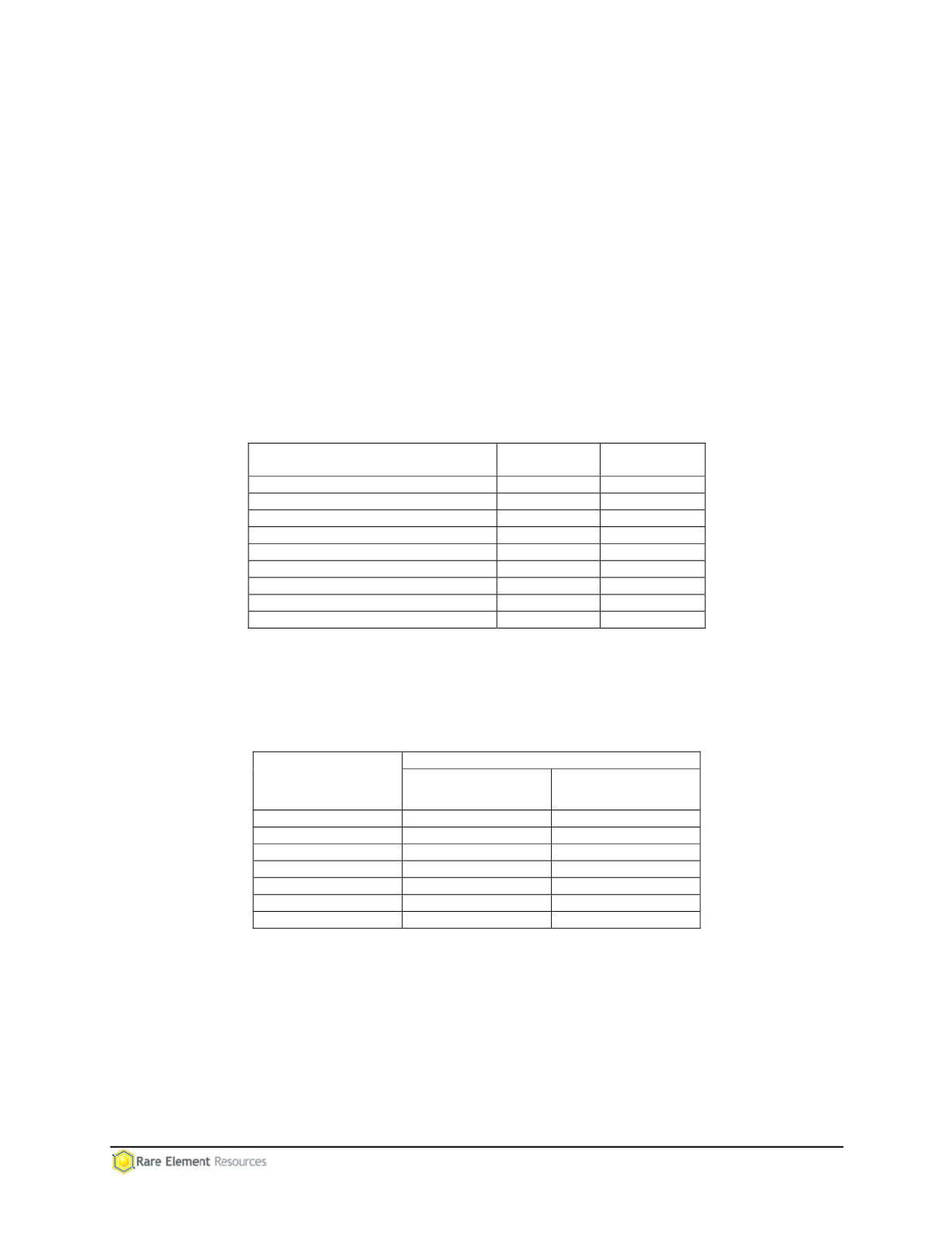

Table 4.7-1

PUG Plant Power Consumption by Area

1

Power Area

Installed

kW

Operating

kW

Crushing Circuit

697

675

Primary & Secondary Classifying

571

552

Grinding and Gravity Classifying

399

388

Magnetic Separation

891

485

Dewatering Circuit

561

412

Water System

336

101

Utilities and Services

399

283

Buildings

600

600

Total

4,454

3,496

4.7.1.2 Water

Raw Water Supply.

Table 4.7-2 provides the maximum estimated daily water consumption

rates for the mine and PUG.

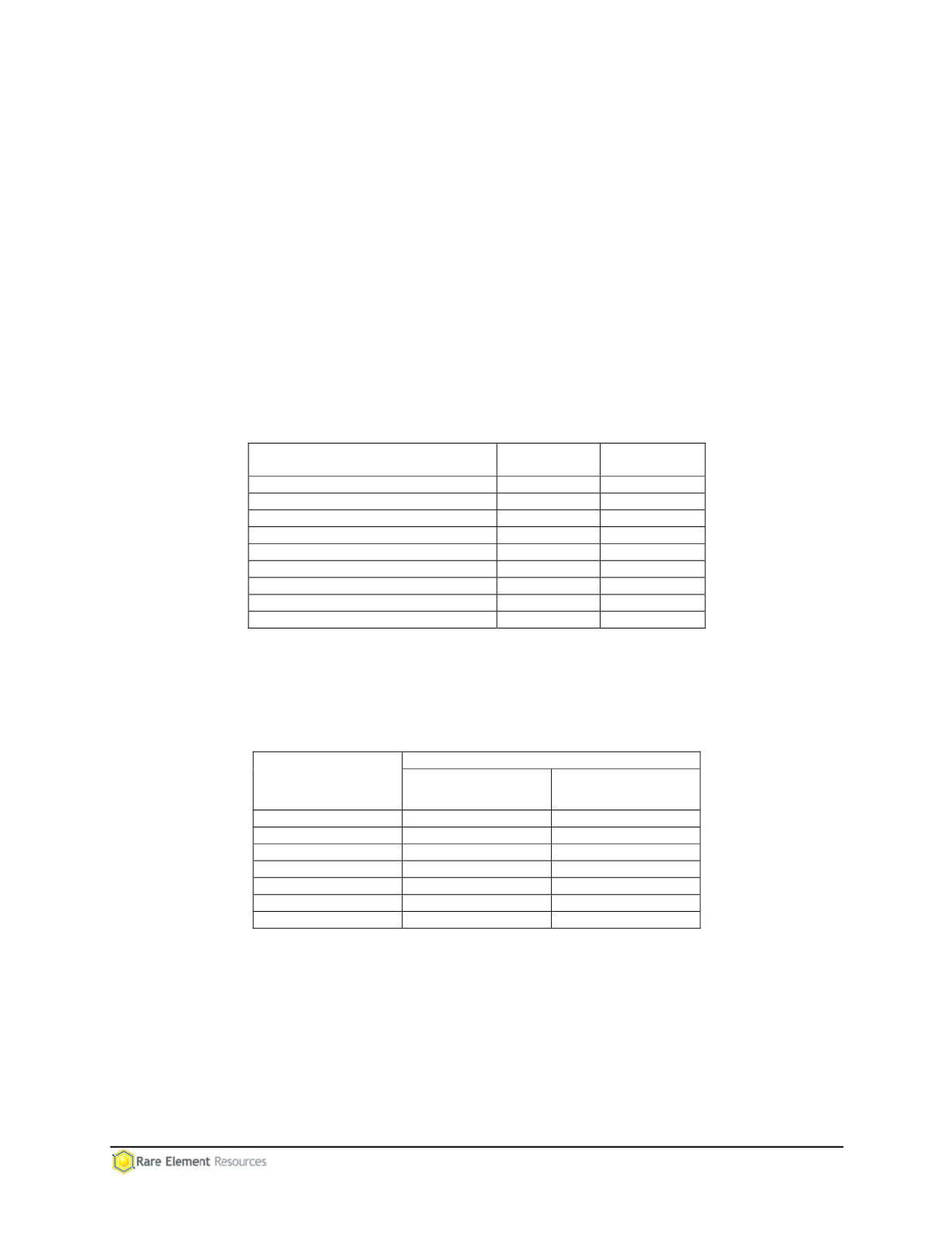

Table 4.7-2

Mine Water Consumption Estimate Summary

Use

Daily

Volume

(gallons)

Rate

(gpm)

Dust Control

21,178

15.0

Truck Wash

1,200

2.5

Potable

11,200

8.0

PUG

60,480

42.0

Sub-total

94,058

67.5

Misc. 10 Percent

9,406

6.8

Total Consumption

103,464

74.3

RER has conducted multi-well pumping tests in three wells located north of the pit (MW-16),

south of the pit (BHD-12-01D), and east of the pit (MW-43), all of which were completed into the

intrusive bedrock hydrostratigraphic unit to evaluate the potential of an on-site water supply

source. The results of the pumping tests indicate that MW-16 would provide the most reliable

long-term source of raw water for mine and PUG operations. This well was pumped at a flow

rate of 100 gpm over a period of 7 days, without significant drawdown in nearby or distant

observation wells. Recoveries in the observation wells to static water levels occurred within 20