Rare Element Resources

Bear Lodge Project

Canadian NI 43-101 Technical Report

October 9

th

, 2014

10135-200-46 - Rev. 0

16-3

Table 16.1 lists the bench face angles (BFA) and inter-ramp angles (IRA) used in the

design of the internal mining phases and ultimate pit. Catch bench intervals are on

20-ft intervals (i.e., single benching) due to generally weak rock mass strengths.

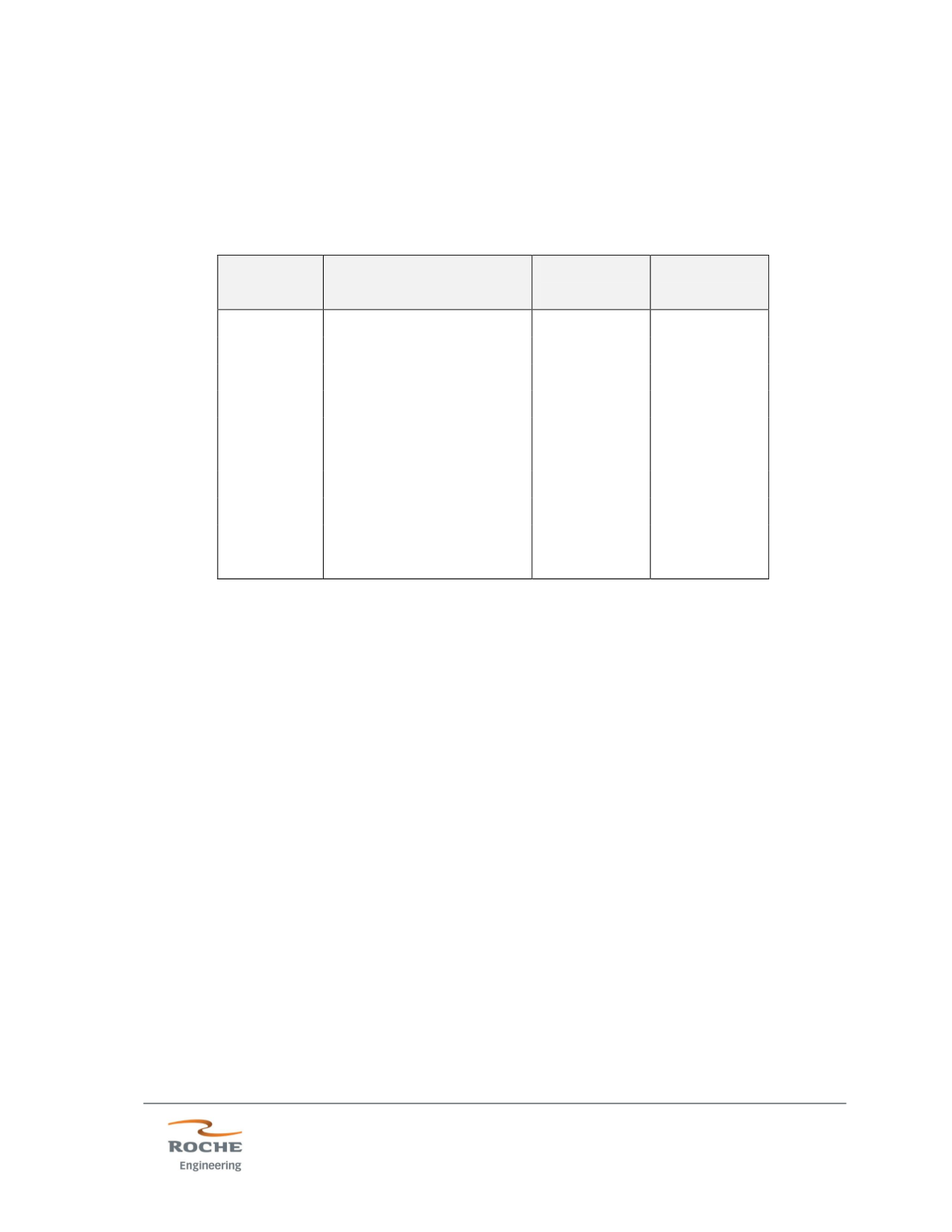

Table 16.1 - Pit Design Inter-Ramp and Bench Face Angles

Sector

Pit Area & Wall Location

IRA

Degrees

BFA

Degrees

1

Bull Hill NW wall

35

64

2

Bull Hill N wall

39

72

3

Bull Hill NE-E wall

39

72

4

Bull Hill S wall

37

68

5

Bull Hill W wall

35

64

6

Whitetail W wall

35

64

7

Whitetail N wall

39

72

8

Whitetail E wall

35

64

9

Whitetail S wall

39

72

10

All areas, 150 ft depth

30

52

(WLRC, 2014)

WLRC modified Sierra Geotechnical’s IRA recommendations in sectors 2, 3, 7 and 9

by flattening 40+° inter-ramp slopes to a maximum of 39°. Additionally, some bench

face angles were adjusted to provide 18- to 19-ft minimum catch bench widths for

worker safety and to reflect typical excavation faces left by mining shovels.

Pit walls were designed to fit selected LG shells, minimizing noses and notches for

slope stability reasons and incorporate internal haulage ramps to allow truck access

to working faces. Ramps were limited to a maximum gradient of 10%. A minimum

pushback (phase) width of 150 ft. was used throughout the design process, with

typical widths ranging from 200 to 250 ft.

16.3 Mineral Reserve Summary By Phase

Seven mining phases were developed and are identified in the order of mining as:

BH1, BH2, WT1, BH3, WT2, BH4, and WT3 (BH signifies Bull Hill phases and WT

refers to Whitetail pushbacks). Phase BH2 is subdivided into two parts: the first,

BH2a, incorporates a temporary ramp on the east wall; and the second, BH2b, mines