Extraction/Separation Technology

Rare Element Resources developed rare earth element (REE) extraction/separation technology in 2013. The patented recovery process resulted in a high-purity, total rare earth concentrate while recycling reagents and water in pilot-plant testing.

World-Class Technology Partner and Majority Shareholder

In 2017, an affiliate of General Atomics (GA), one of the largest, most advanced technology companies in the world, took an equity position in Rare Element Resources. As a leader in new technology development, both commercially and for national security, GA is aware of the importance of developing a secure, domestic supply of critical REEs. The Company, our proprietary recovery process, and the Bear Lodge Project are the cornerstones of their efforts.

Since then, GA and its partners have brought the full force of their technology development team to refine and enhance the extraction/separation process. In 2020, the first high-grade, separated REE product (neodymium/praseodymium) was produced from Bear Lodge material. This was done at a lower cost and in a more environmentally sound way than traditional industry methods.

The Process

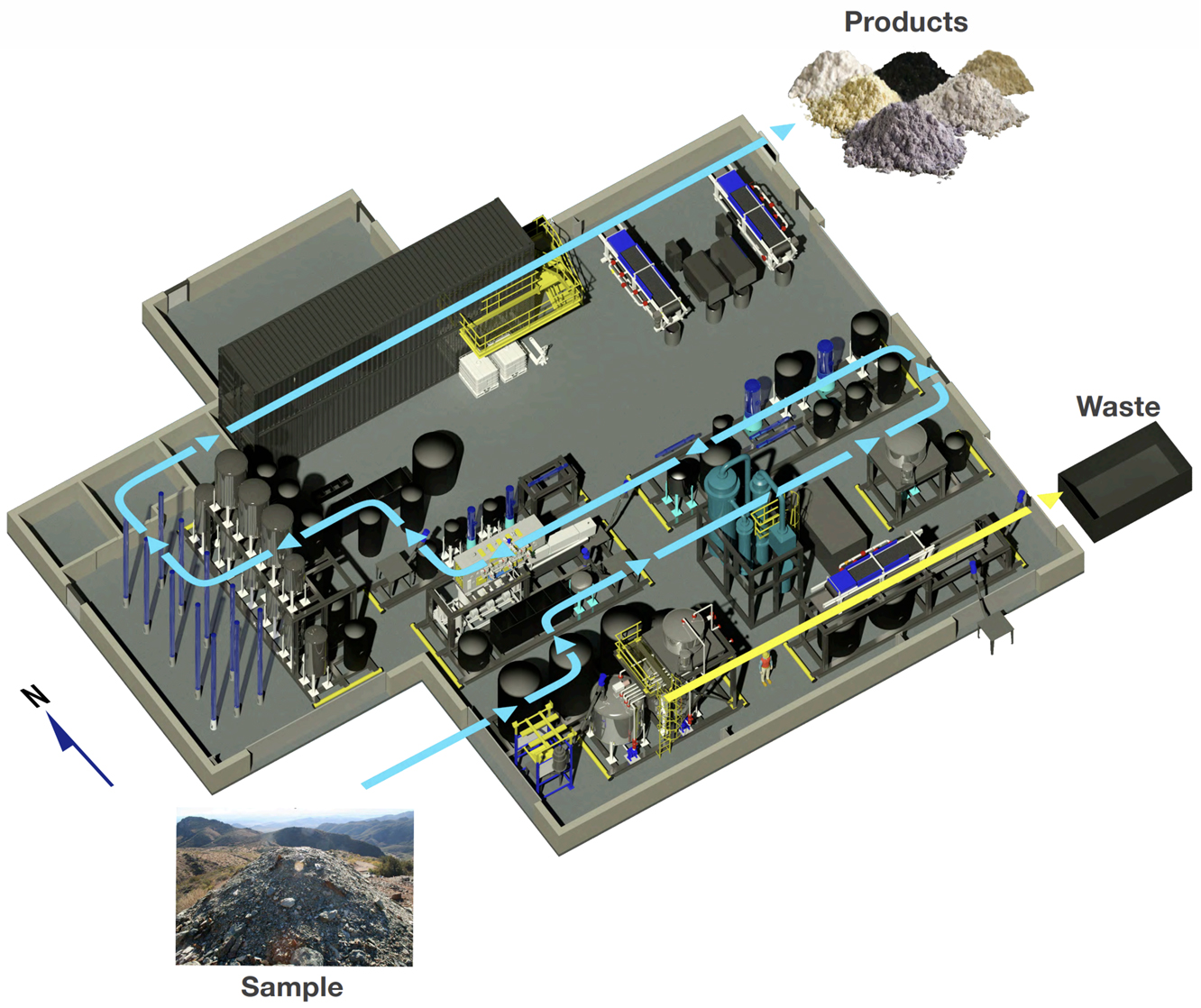

Extensive pilot-plant testing was undertaken at Europe’s Umwelt-und-Ingenieurtechnik GmbH (UIT) labs in Germany. General Atomics Electromagnetic Systems (GA-EMS) and LNV, an Ardurra Group, Inc company, were integral members of the team. The process involves four steps:

Step 1: Physical Upgrading – crushing and screening of the feed sample to 1mm sizing allowing for more surface area for the subsequent steps.

Step 2: Primary Hydromet Processing – counter-current leaching and selective precipitation separates out the waste and a majority of the naturally occurring radioactive material normally associated with REEs.

Step 3: Separation and Refining – chemical digestion and solvent extraction, removes the thorium and cerium (not currently a marketable REE). The process allows for a high recycling rate of process streams and a significant reduction in the production of waste material.

Step 4: REE Separation/Refining – a multi-step process allows for removal of the Nd/Pr at a >99.5% purity (high demand magnet material), as well as SEG (samarium/europium/gadolinium), lanthanum and a heavy rare earth concentrate.

Demonstration Plant

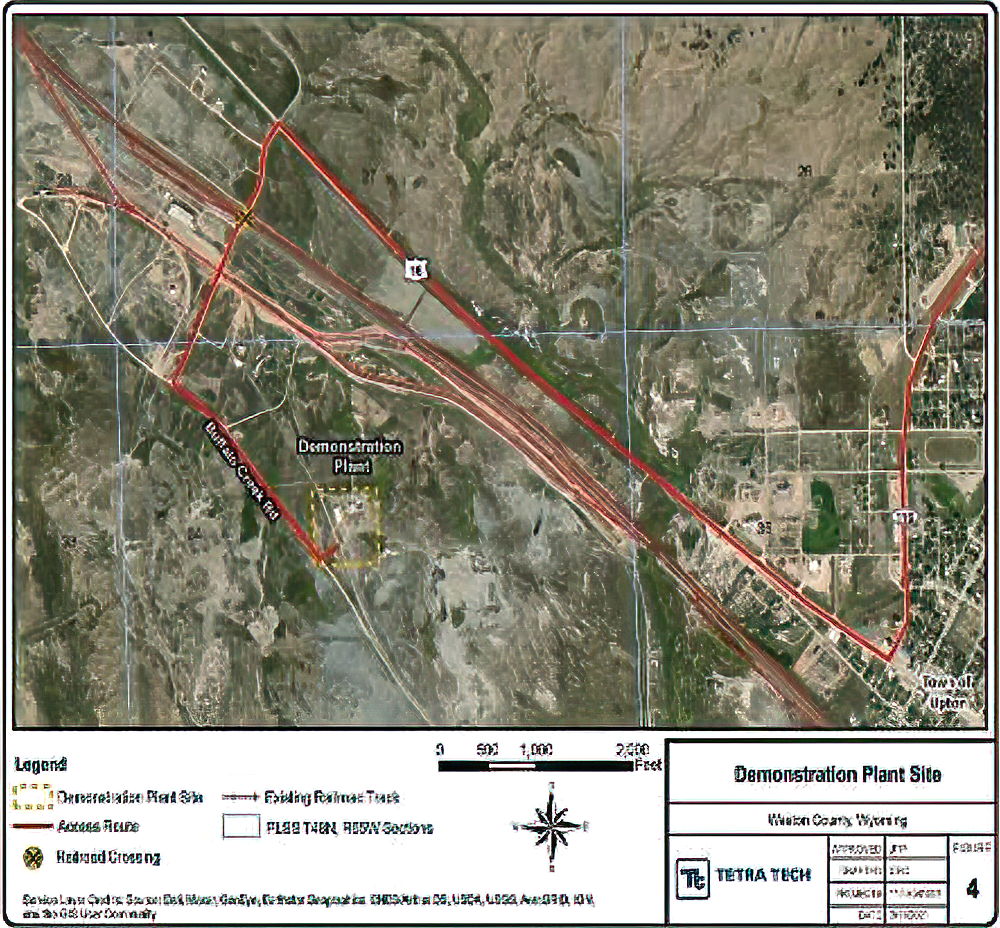

The primary goal of the Demonstration Plant is to validate the Company's REEs extraction/separation process at a scale sufficient to provide design and performance data, as well as economic metrics for a potential follow-on, commercial-scale extraction/separation facility. In 2021, the partners announced completion of a financial award from the U.S. Department of Energy (DOE) Advanced Manufacturing Office in the amount of $22M. This money is dedicated to the design, permitting, licensing, construction and operation of the planned demonstration plant. Further, in November 2022, the Company was named a grant recipient from the Wyoming Energy Authority (WEA) for an additional $4.4M to support non-federal costs. Collectively, these funds will cover more than half of the initial budget of $44M.

As of early 2023, the development team and the DOE have completed design of the demonstration plant, which will be built in Upton, WY. The Nuclear Regulatory Commission (NRC) license was received in late July 2023, and the DOE NEPA review was completed in mid-November with construction commencing in December 2023. In September 2024, the DOE confirmed the construction completion and approved the commencement of the commissioning of the plant and DOE committed an additional 10% to its cost-share, resulting in a total contribution of $24.2M in support for the plant. Operations are expected to commence in 2025, following shakedown and construction updates.

REE Processing Demonstration Plant

Located in Upton, Wyoming

.jpg?sfvrsn=2)