Rare Element Resources

Bear Lodge Project

Canadian NI 43-101 Technical Report

October 9

th

, 2014

10135-200-46 - Rev. 0

14-41

14.14 Block Model Density Estimation

Densities were estimated for each block based on the fraction of FMR/carbonatite

mineralization, which was estimated using IDP estimation and the same procedure

used for estimating the rare-earth-element grades. The formulae used for the block

model density estimates are summarized in Table 14.24.

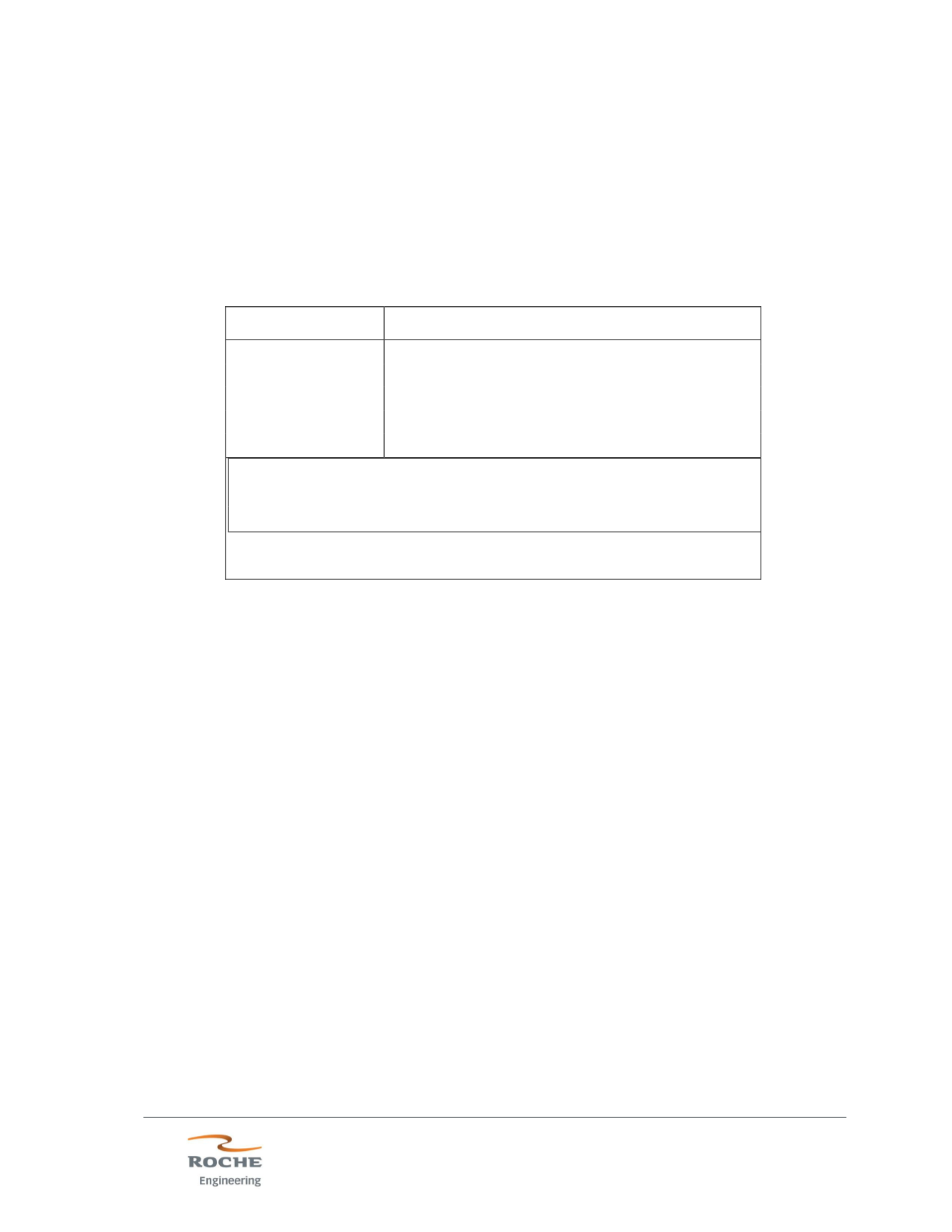

Table 14.24 - Formulae for Block Density Estimation

Oxidation Type

Density Formula (t/m

3

)

Overburden & Clay

1.8

Oxide

0.01*(REminIDP*1.81 + (100-REminIDP)*2.26)

OxCa

0.01*(REminIDP*2.16 + (100-REminIDP)*2.32)

Trans

0.01*(REminIDP*2.32 + (100-REminIDP)*2.55)

Sulfide

0.01*(REminIDP*2.91 + (100-REminIDP)*2.59)

Where, REminIDP is the IDP estimate of the percentage of FMR and

Carbonatite. Default density is assigned to blocks with no REminIDP

estimate using a value of zero (0.00) for REminIDP.

Metric densities are divided by 32.026735 to convert from t/m

3

to short

tons/ft

3

.

(A.Noble, 2014)

14.15 Dilution

Dilution is incorporated into the resource model through two separate mechanisms:

first, geometric dilution is incorporated by compositing; and second, volume-variance,

or block-smoothing dilution is incorporated by adjusting the parameters of the

inverse-distance-power grade estimation method.

The purpose of geometric dilution is to smooth out local geometric variability, to

enhance overall continuity by defining larger, more regular shapes, and to group the

data into higher-grade, primarily dike mineralization, and lower-grade, primarily

stockwork mineralization. In addition, mineable-width mineralized zones are created

for mine planning.

Geometric dilution is incorporated when true-width composites are computed using

20 to 30-foot minimum horizontal widths for definition of OreZONE codes. Compared

to the original assays, which are nominally five-feet long and broken at major

contacts, such as high-grade dikes, the OreZONE composites introduce 71% dilution

and reduce ore grade by 33%. In addition, there is a 21% loss of ore-grade intervals