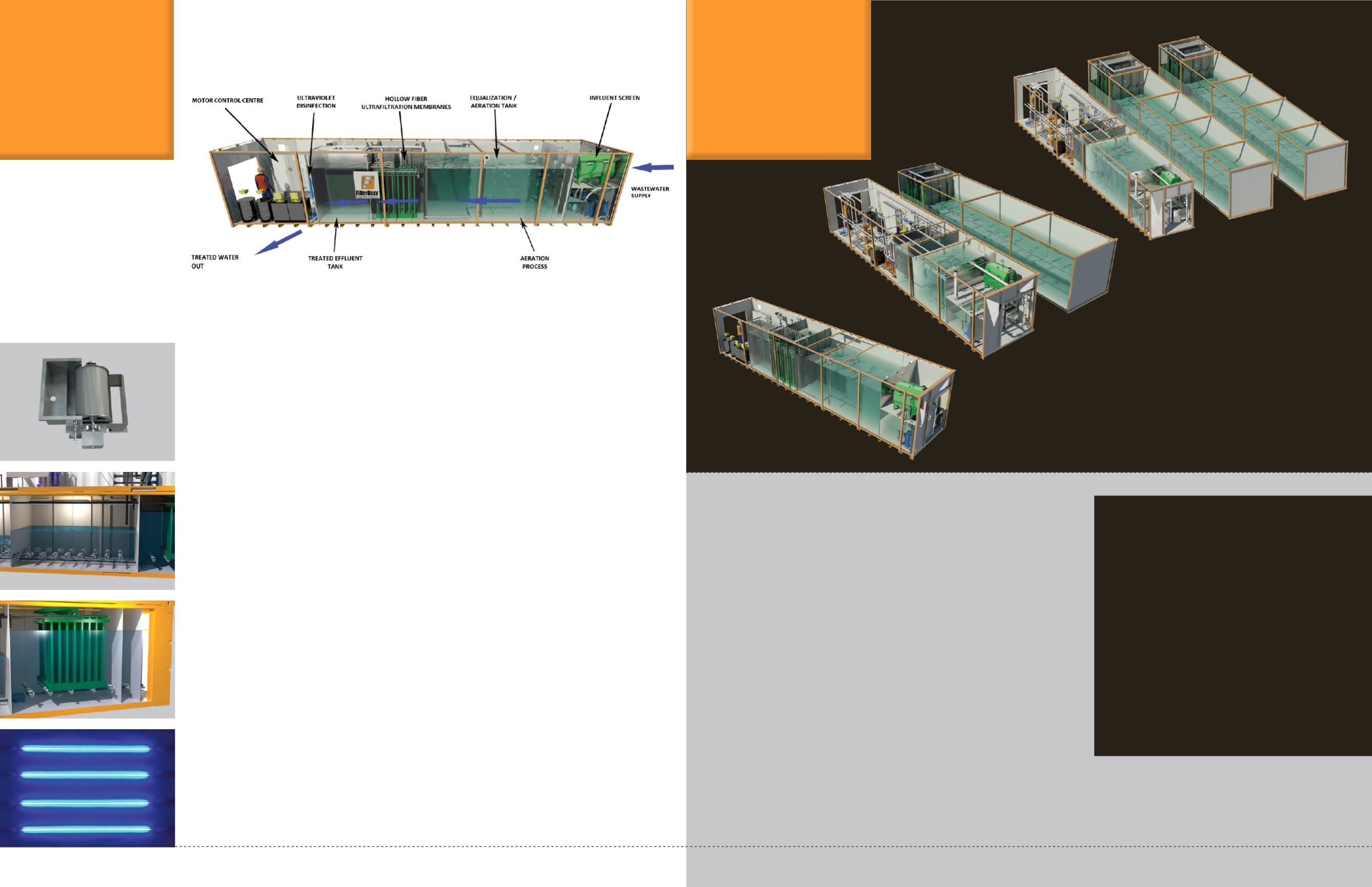

INLET SCREEN

The raw water inlet screen removes all debris larger than 2mm and is a self cleaning design.

Examples of screenings include fibrous materials such as hair and non-biodegradable materials

such as plastics. Screening the influent stream prior to entering the aeration tank enables the

MBR system to operate more efficiently and ensures longer trouble free operation of membranes

and process equipment.

EQUALIZATION / AERATION TANK

Fine bubble diffusers with variable blower capacity allows the equalization tank to operate as

an aerobic zone achieving the desired dissolved oxygen levels. The aeration is sized to provide a

robust process at a higher biomass concentration. It is inherently stable and resistant to organic

and hydraulic shock loading therefore reducing the footprint size of the plant.

MEMBRANE FILTRATION

The heart of an effective wastewater plant is the membrane bioreactor (MBR). Combining proven

biological treatment processes with hollow fiber membrane technology to treat wastewater, the

MBR offers a superior alternative to other process options. In addition, these membrane systems

can handle large variations in feed solids which would normally lead to an upset condition, thus

proving them as a robust barrier to wastewater solids. The membranes are submerged in partially

treated waste water and treated effluent is drawn through the membrane, ensuring a high standard

of treatment in a small footprint area. The membranes also trap a significant portion of pathogenic

organisms allowing for more efficient disinfection. Daily chemical cleaning of the membranes are

controlled automatically through the PLC.

ULTRA VIOLET DISINFECTION

Ultraviolet (UV) disinfection is effective at inactivating viruses, spores and cysts by destroying

the cell’s ability to reproduce. There is no residual effect that can be harmful to humans

or aquatic life. It is user-friendly to operators and eliminates the need to store and handle

potentially harmful chemicals.

TREATMENT PACKAGE INCLUDES

•

Fully engineered and approved design

•

Complete system documentation

•

Electrical, mechanical and interconnecting piping supply and assembly

•

Fully automated controls

•

Alert/alarm indicators with audio and visual indicators

•

Control panel, PLC and touch screen controls

•

NEMA 4 electrical equipment with CSA approved installation

•

PVC process piping

•

Electrically-fired heating and ventilation system

•

Safety equipment

•

Conforms to Canadian building codes

EFFLUENT TREATMENT PARAMETERS

UNMATCHED Effluent Quality

•

CBOD

5

:

< 10 mg/L

•

TSS:

< 10 mg/L

•

Total coliforms:

< 1,000 CFU/100ml

•

Fecal coliforms:

< 200 CFU/100ml

•

Additional treatment options are available, including nutrient removal

and sludge handling

INDUSTRY LEADING DESIGNS

|

WORLD CLASS TECHNOLOGY

|

HIGH QUALITY PARTS AND FABRICATION

|

COST CERTAINTY

|

SERVICE SATISFACTION

|

OVER 10 YEARS EXPERIENCE

INDUSTRY LEADING DESIGNS

|

WORLD CLASS TECHNOLOGY

|

HIGH QUALITY PARTS AND FABRICATION

|

COST CERTAINTY

|

SERVICE SATISFACTION

|

OVER 10 YEARS EXPERIENCE

THE TREATMENT PROCESS

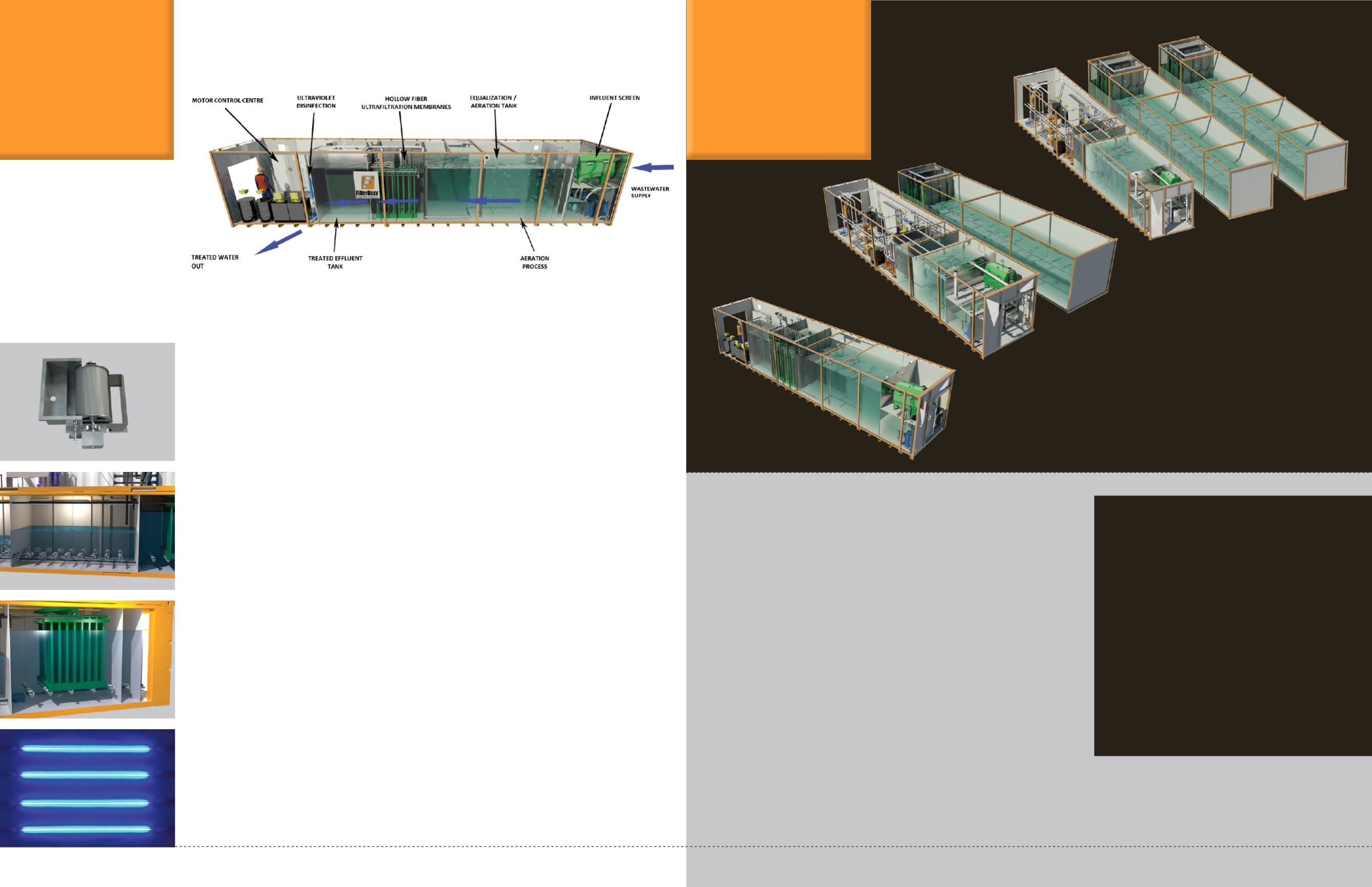

STANDARD SIZE BUILDINGS

The Treatment Plant is portable, insulated,

heated, steel constructed and designed for

harsh climates. Pre engineered building

lengths are 50’ and 60’ depending on flow

and optional equipment.

Complete systems can be transported to your

location via ship, truck, plane or train.

STANDARD SIZES & DESIGN FLOWS

•

38m

3

/ day flow

•

75m

3

/ day flow

•

150m

3

/ day flow

•

300m

3

/ day flow

COMPACT, PRE-ENGINEERED MBR

WASTEWATER TREATMENT PLANTS

C-SERIES

300 m

3

/ day

150 m

3

/ day

75 m

3

/ day

MODULAR

DESIGNS